INDUSTRIAL TECHNOLOGY

- PLANT ASSESSMENT TECHNOLOGY

-

Advanced Nuclear Measurement and Imaging

Radioactive isotopes, particularly in the form of radioactive tracers and radioactive sealed sources, have been used over a broad spectrum of process industries for equipment and process troubleshooting, monitoring, control, inspection, optimization and many other purposes.

Plant Assessment Technology Group (PAT) is a research group under the Industrial Technology Division in Nuclear Malaysia. Group core research is in application of sealed source and radiotracer technologies in industries. The activities include providing process diagnostics services through the usage of gamma ray column and pipe scanning techniques, neutron level scanning as well as radiotracer techniques to petrochemical plants, industrial facilities, water treatment plants and other facilities. PAT promotes both sealed source and radiotracer techniques by participation in national seminars, providing training and technical consultancy to interested parties.

Objective:

- To utilize sealed source and radiotracer techniques as process diagnostics tool in the industrial sector (oil and gas, process & energy industries) and agriculture sector (sustainability of tree crops (e.g. palm oil, gaharu), and local urban trees & shrubs)

- To provide technical support and services in process diagnostics, and technical training in radioisotope technologies for Malaysian industries.

- To establish a diagnostics center for advanced nuclear measurement and imaging services

Research and Development:

X-ray

- Computed Tomography (CT)

Gamma

- Gamma Computed Tomography (CT)

Neutron

- Prompt Gamma Neutron Activation Analysis (PGNAA)

- Moisture/Density Gauge

Industrial Radiotracer

Radioactive Particle Tracking (RPT)

-

X-Ray Computer Tomography (CT)

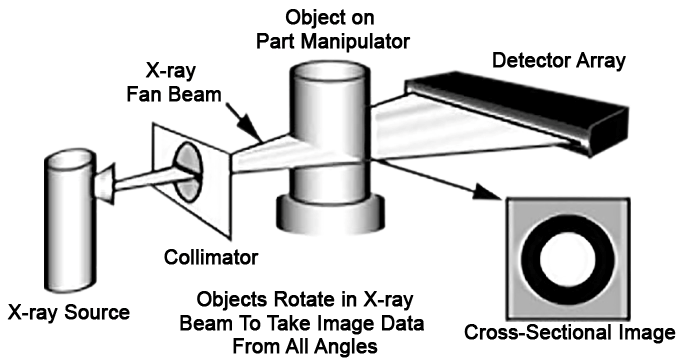

X-ray Computed tomography (CT) is an imaging procedure that uses special x-ray equipment to create detailed images of an object's inner structures in 2-D or 3-D. A beam of x-rays is aimed and rotated around a sample, producing signals that are processed by the machine’s computer to generate 2-D cross-sectional images-or "slices"-of the sample. These slices are called tomographic images. Once a number of successive slices are collected by the machine’s computer, they can be digitally "stacked" together to form a 3-D image that represent the structure of the sample.

A schematic of a CT system

Equipment

1. X-Ray CT

X-Ray CT (Voltage: 160 kV, Current: 5.0 mA, F.O.C: 1.0, 3.0)

Left: Sample, Right: reconstructed x-ray tomographic images of tree cutout sample

2. X-Ray Mikro CT

X-Ray Mikro CT

- Voltage: 100kv, Geometry - Sample: 4cm

- Micro CT scanners are typically used for small animals, biomedical samples, foods, microfossils, and other studies for which minute detail is desired.

- Micro CT is superior for spatial resolution which is in the micrometer range.

- Suitable for solid sample with moderate density

Advantages of CT:

- Provides a non-destructive technique to investigate the internal structure of a sample

- CT eliminates the superimposition of structure image outside the area of interest

- Digital image of CT can be manipulated by user for image enhancement

Application of CT:

- Industry

- Agricultural

- Medical

- Aerospace

- Geosciences

- Archeology

-

Gamma Computer Tomography

Just like X-ray Computed tomography (CT), gamma CT is an imaging procedure that uses gamma ray to provide a two dimensional (2-D) cross-sectional view of the interior of an object. Gamma-ray transmission tomography is based on the principle of measuring the attenuation of a beam of radiation transmitted through an object. The attenuation of gamma-rays is highly correlated to the atomic number and density of materials.

The gamma-ray transmission data are collected by radiation detectors at many different angles within the image plane, and these data are then used to reconstruct a cross-sectional image that is essentially a map of the density distribution.

Equipment

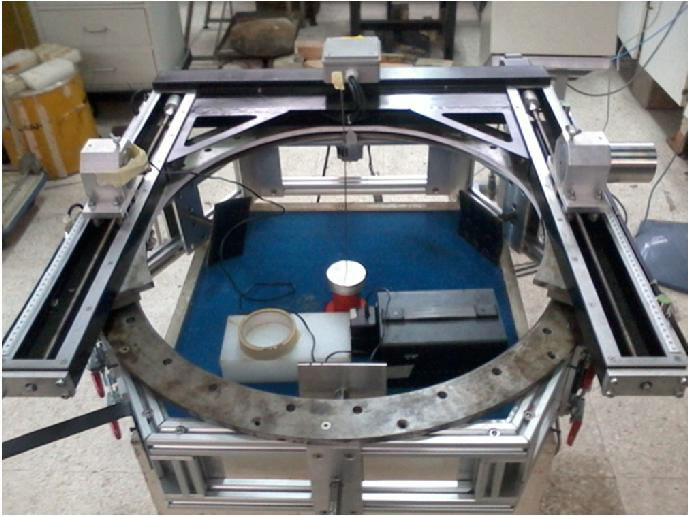

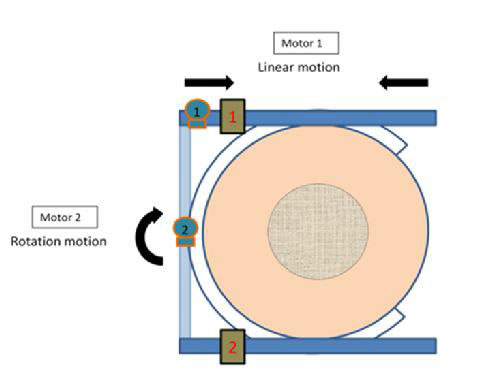

Gamma Tomografi

- Source: Am-241, Ba-133

- Energy: 100mCi

- Two detector system

- Linear step movement (min 0.5cm)

- Rotation of 180 Degree (min 1 degree)

- Data acquisition and processing using LabVIEW software

Gamma Proses CT

Source Holder and Collimator

9 Detectors

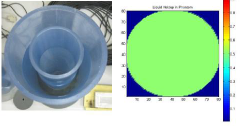

Left: phantom, Right: reconstruction image

Detector Collimator

Gamma Process Tomography

- Source: Cs-137

- Activity: 100mCi

- Scanning and imaging of process bubble column

Research Project

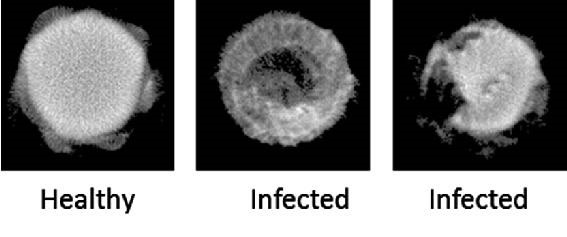

- GammaScorpion: Mobile gamma-ray tomography system for early detection of basal stem rot in oil palm plantations

GammaScorpion at site

Results from GammaScorpion

-

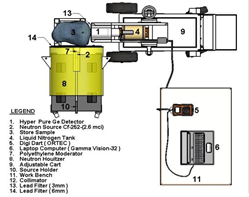

Prompt Gamma Neutron Activation Analysis (PGNAA)

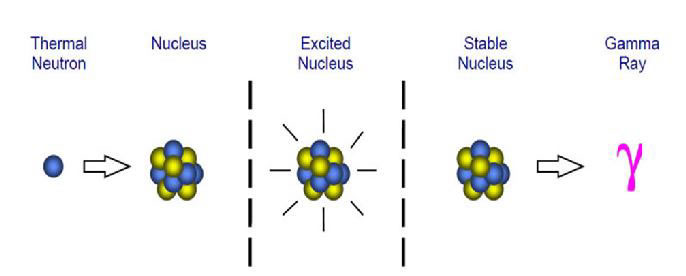

Prompt Gamma Neutron Activation Analysis (PGNAA) is a technique to identify elements and its concentration in a sample by neutron irradiation. It is a nondestructive method, which provides real time analysis through continuous measurement of the elemental composition of the material under test. The sample is continuously irradiated with a beam of neutrons from a californium-252 source. The elements of the sample absorb these neutrons and emit prompt gamma rays which are detected by Hyper Pure Ge (HPGe) detector.

Each element emits a unique gamma ray. The energies of these gamma rays identify the neutron capturing elements and the intensities of the peaks at these energies reveal their concentrations.

PGNAA Process

Setup

- Neutron source: Cf-252

- Activity: 2mCi

- Energy <10 MeV

- Detector: HPGe detector

Instruments

HPGe Detector

Collimator Detector

Digidart

Liquid nitrogen container

Typical elements that can be identified:

- Iron (Fe)

- Aluminium (Al)

- Silicon (Si)

- Potassium (K)

- Sulfur (S)

- Calcium (Ca)

- Magnesium (Mg)

Advantages of PGNAA:- Fast scans

- Ease of sample preparation

- Simultaneous measurement of multiple elements

- Offer more sensitivity, accuracy and reliability than other methods

Application of PGNAA:- Industry (cement, mineral, iron ore, steel, slurry, mining)

- Archeology

Research Project- In-Situ Compositional Analysis and Provenance Study of Historic Terengganu Stone (The Inscribed Stone “Batu Bersurat”) using Neutron – Induced Prompt Gamma Ray Technique (NIPGAT)

Equipment setup in progress

Scanning at original Terengganu Inscribed stone

Layout of the radiation source and the detector HPGe against stone inscription

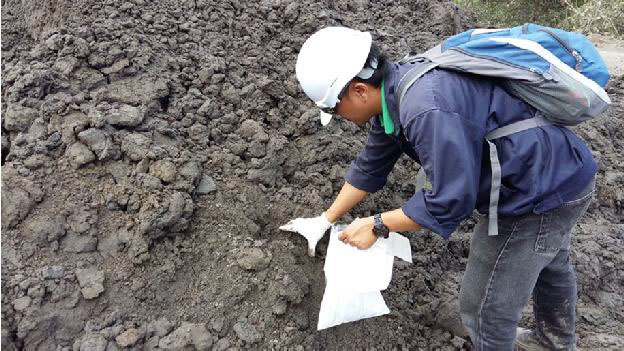

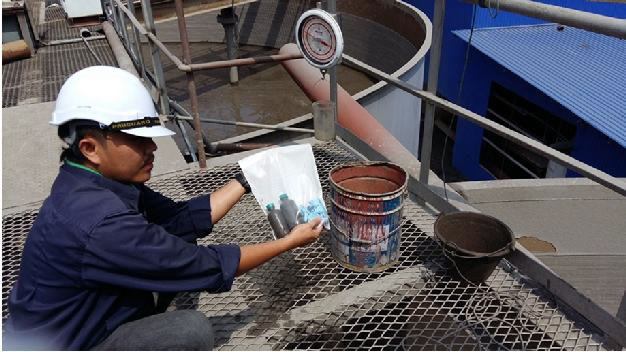

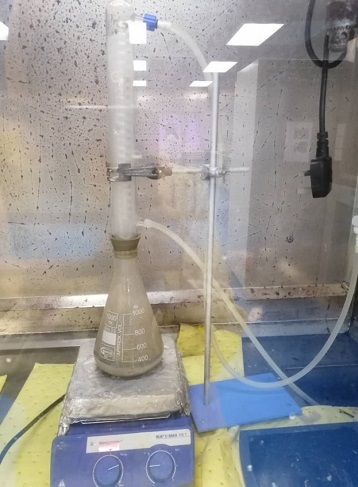

- Multi-elemental Analysis in Tin Tailings Processing Plants using PGNAA Technique (IAEA/Coordinated Research Project –F22065):

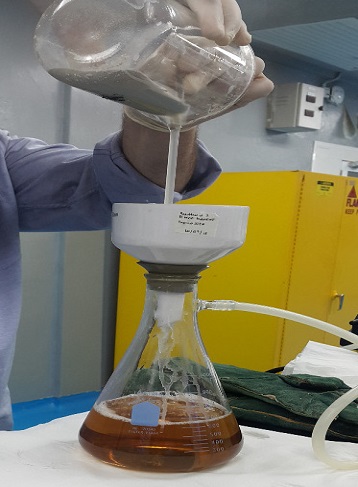

Collection and preparation of sample

-

Industrial Radiotracer

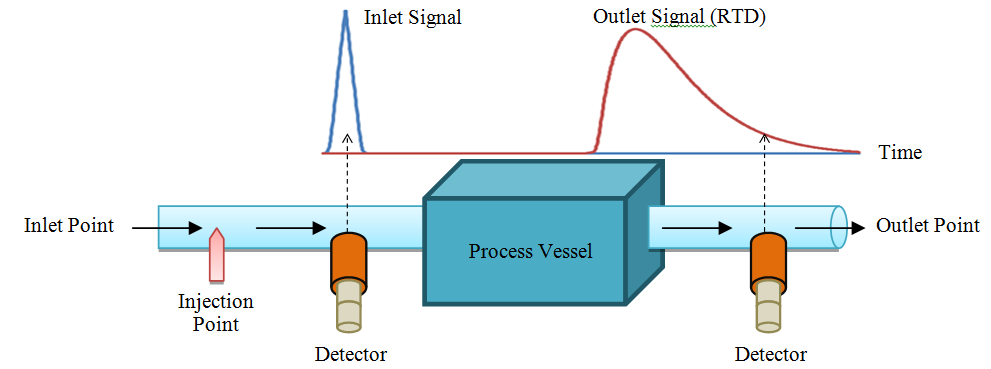

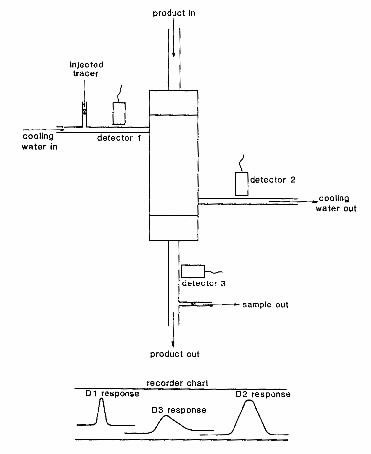

Radiotracer is a non-invasive technique to quantify the flow behavior of any multiphase system. In recent decades, there has been a trend towards using radiotracer techniques for assessing flow field in industrial vessels.

The injection of radioactive material in a suitable physicochemical form similar to that of the process material. The passage of these radiotracers through the system of interest is monitored at strategically selected locations using radiation detectors.

Radioisotope tracers are widely used for various industrial uses such as:- Petroleum and petrochemicals

- Mineral processing sector

- Wastewater treatment plant

- Power Generation

Radiotracer technology been performed to industries for:- Flow rate measurement

- Resident time distribution (RTD) measurement

- Leak detection

- Mixing and blending studies

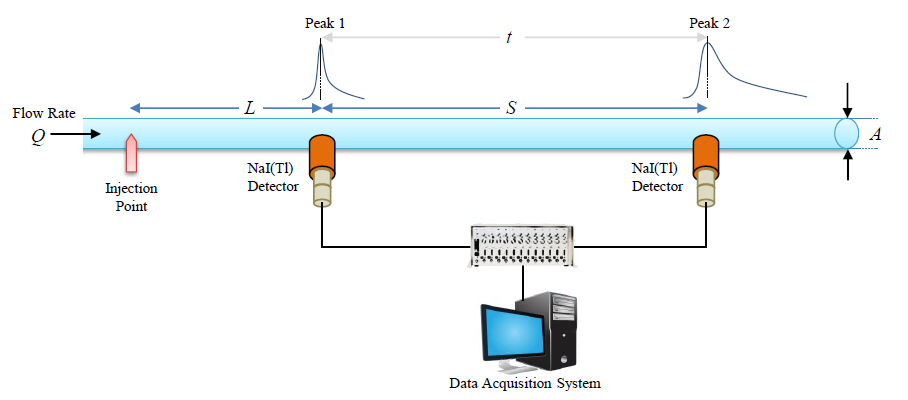

Flow Rate Measurement

The Radiotracer techniques was designed to measurement the flow rate in petroleum, chemical process industries and power generation for identifying and locating the volumetric flow rate of stream/ pipeline/heat exchangers in industrial process plants.

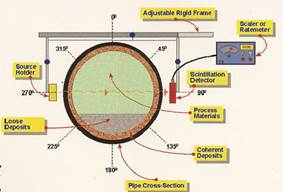

Principle of flow measurement method

Residence Time Distribution (RTD)

The concept of residence time distribution (RTD) has become an important tool for the analysis of industrial units and reactors. The RTD of fluid flow in process equipment determines their performance. Radiotracers are method of choice for obtaining the RTD in industrial processing vessels and wastewater treatment systems.

Principle of RTD Method

RTD investigation at the Waste Water Treatment PlantLeak Detection

A radiotracer technique for leak detection is applied in industries for identifying, locating and quantifying the leakage of heat exchangers in industrial process plants. This technique is involves the injection of a suitable radiotracer into the process stream, which is suspected of leaking, and seeking the presence of that tracer in the outlet. This can be done either by using sensitive radiation detectors mounted externally on the outlet pipes or heat exchanger systems.

Principle of Leak Detection Method

Advantages of Radiotracer:

- High detection

- Sensitivity, on-line detection and availability of

- A wide range of compatible radiotracers for various applications

- Utility in harsh industrial environments

- Offers minimal radiation exposure compared to the conventional method

Application of Radiotracer:- Petroleum refining

- Petrochemicals process

- Bulk chemicals

- Polymers and materials

- Food processing

- Pharmaceuticals

- Fine chemicals

- Environmental waste management

-

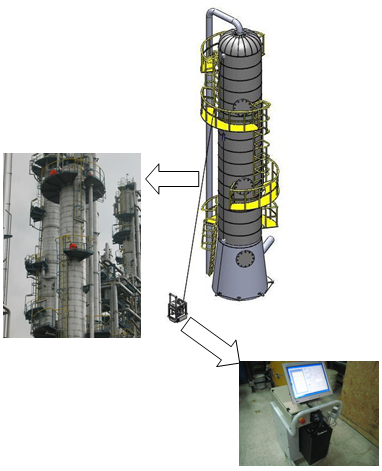

Column Scanning System

Column scanning uses a gamma ray scanning system for industrial processing column inspection and diagnostic. It is a gamma ray scanning tools for direct investigation and problem solving of industrial processing column and this system has been developed by the Malaysian Nuclear Agency.

The system offers to identify some common faults in the column:

- Missing or damaged trays, demister pads and packaging

- Corrosion causes partial tray damage

- Missing, collapsing or buckling trays or manways

- Liquid or vapor distributors Out-of-place trapping (slight, moderate, severe, jet flooding)

- Moaning or dumping of trays

- Trays dry or flood due to loading conditions

- Uneven liquid levels on trays and in box, trough and Collection separations

- Foaming on trays or in reboilers, condensers and accumulators

- Maldistribution of vapors and liquids in solids

- Liquid holds up due to plugs and extreme hot dirt or subcold feed or reflux

-

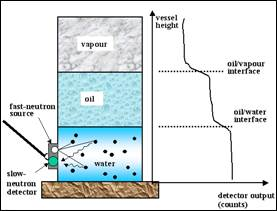

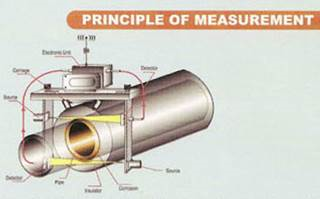

Spot Vessel Scanning System

This system using the neutron backscatter technique. Portable nucleonic system for measuring spot level or material interface in process vessel, storage tank, or pipeline.

This system offers:

- Perform non-contact or non-invasive measurements.

- Provides immediate checkpoints or rapid indication of process changes with advanced mobile tracking techniques.

- Can be used for all tanks / vessels regardless of diameter size.

- Use computer assistance for data acquisition and analysis systems to provide fast, accurate and reliable results.

-

Pipe Scanner System

Portable nucleonic gauges for non-destructive detection for blockages and deposits of material in insulated or uninsulated pipelines in industrial processing plants. A quick way to find and measure the thickness of deposits without having to shut down / stop the process of a plant.

Deposited material in the pipeline scanning is in progress

Diagram arrangement of scan results

-

Moisture Detector

Using the neutron backscatter technique. Portable nucleonic system for measuring areas of moisture in soil or concrete bridges.

The system offers:

- Perform non-contact or non-invasive measurements.

- Provides instant confirmation or immediate indication of process changes with advanced mobile tracking techniques.

- Can be used for all concrete or ground bridges.

A moisture detection scan is in progress

-

Corrosion Under Insulation (CUI) Profiles for Pipes

A new portable nucleonic system for non-invasive quantitative detection of corrosion under insulation for steel pipes. Corrosion on the outer walls of insulated steel pipes is a major problem of industrial plants. The critical area that occurs is the area around the pipe weld/joint. Industry estimates that nearly 95% of oil & gas plant, chemical plant and power generation failures are due to pipeline problems.

Various methods have been studied to monitor corrosion in pipelines. Nevertheless, no conventional NDT technique is capable of detecting corrosion under insulation (CUI), in a practical and cost-effective manner. To overcome this shortcoming, a new system called “Corrosion under insulation detector for pipes” has been developed. A portable nucleonic system can be used to detect CUI without the need to remove insulating materials. This system can be performed while the plant is operating and subsequently loss of production due to unnecessary closure of the manufacturing process can be avoided.

The system offers:

- Fast scan, about 6 meters per minute

- On-line measurement; therefore cost savings, no shutdown time.

- No insulation needs to be removed and pipe preparation is not required.

- Not affected by process temperature, pressure, viscosity, abrasives and other environmental hazards.

- Computerized data acquisition and analysis with profiling software.

- Safe to use as a system that uses a small “sealed source” that has with radiological safety features

-

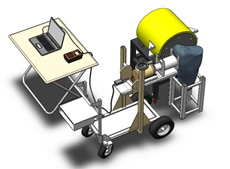

Multi-Phase Flow Rate Investigations

The facility is comprised of acrylic pipe with an inner diameter of 100 mm wide and a total length of 35 meters to ensure the flow pattern is fully developed. Air and water flow rates can be adjusted to produce different flow patterns. Most common flow patterns such as bubble flow, stratified flow, plug flow and annular flow can be produced by adjusting the flow rate in different phases.

The system offers:

- Flow meter facility to study the distribution flow pattern, velocity and mass flow rate in liquid-liquid-gas flow.

- Suitable for flow meter designers to test new products before applying them in real industrial fields.

- Provides 1/8 scale for industrial flows.

-

Historical Artifact Studies

NIPGAT is a non-destructive technique used to identify elements and determine the concentration of those elements in a sample using neutrons. This method is based on the detection of gamma rays emitted by samples during neutron irradiation (Cf-252). Then, the elemental concentrations will be obtained for the already identified elements.

The system offers:

- This method is useful as an analytical technique for both qualitative and quantitative methods of identification of various major, minor and trace elements present in the sample.

- For most elements and applications, this technique offers more sensitivity, accuracy and reliability compared to other conventional methods.

- NIPGAT does not require special preparation of samples.

Top view

3D view

The process of preparing equipment to scan the Terengganu ‘Batu Bersurat’

-

Low Cost X-Ray Computed Tomography System

Is a tool that uses powerful non-destructive imaging techniques to view the internal structure of an object in 2D or 3D cross-sectional image without having to physically grind the part. The invention of computed tomography (CT) techniques has revolutionized the field of medical diagnostic imaging as it provides more detailed and useful information than previous non-destructive imaging techniques. This method is increasingly used in industry, aerospace, geoscience and archeology.

Engine bracket and reconstruction of x -ray tomography images

Fuel filter and reconstruction of x -ray tomography images

-

Compaction Control for Civil Works

Compaction is a process of reducing air voids in reclaimed soil and earth by means of rolling, shock, vibration or other means. Compaction is an important factor in the construction of highways, dams, buildings as well as other types of basic civil engineering structures.

Nuclear Malaysia offers services for:

- Highways (soil, stone-soil aggregates, concrete, asphalt treated foundations, asphalt surfaces, asphalt pavements)

- Fortress (airport, car park, reclaimed land)

- Soil walls (dams and prefabricated sites)

- Load -bearing sites

- Drainage base for storm / sanitary sewers

- Drainage

Soil for roofing material as a result of imperfect compaction:

Asphalt fatigue: if left unrepaired will lead to more serious damage

Site erosion

Collapse of road or car park

Sediment of drainage system

Ongoing maintenance and rehabilitation work meets the demand to improve the quality and safety of the road network in Malaysia.

Data measurement is in progress.

-

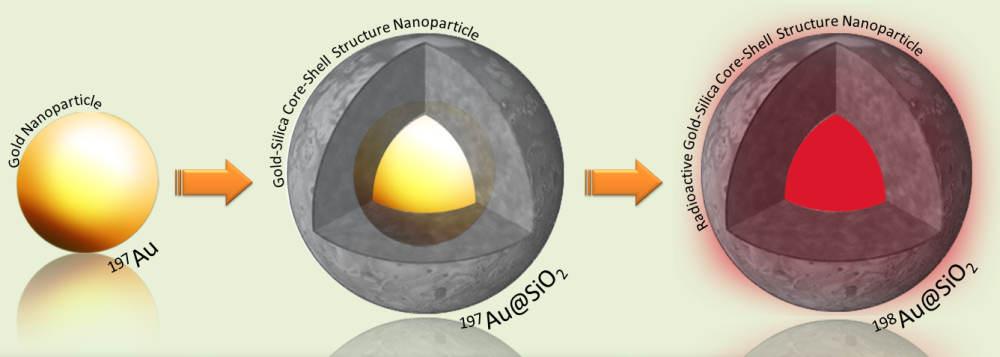

198Au@SiO2 Nanoparticles - Industrial Radioactive Tracers

198Au@SiO2 nanoparticles for innovative use in industrial research processes using industrial radioactive tracer technology. This approach is taken to create something worthwhile in the field of nanotechnology that is geared towards the target material of the core nanoparticles-shells, namely 198Au@SiO2 to be used innovatively in industrial process research using radio detection techniques. Synthesis methods for spherical-structured core-shells, 197Au@SiO2 were using gold salts to produce gold colloids (size 30nm), Tetraethyl orthosilicate (TEOS) as precursors, and ammonia as catalysts. A 197Au@SiO2 core-shell sphere with one Au nanoparticle was obtained through this innovative method.

The main purpose of this work is to introduce fine nanoparticles in solid form that go through the process of neutron irradiation to produce 198Au@SiO2 radioactive tracer. Most of its applications require the nanoparticles to be chemically stable at high temperature, uniform in size and well-dispersed in liquid media. SiO2 coated Au nanoparticle were loaded into a Malaysian Nuclear Agency research reactor TRIGA-MARK II for neutron bombardment that converts Au to the radioactive Au-198 isotope.Advantages:

- Most appropriate tracer with half-life 2.7 days and 99% abundance of gamma rays energy at 412keV.

- Can be produced in a relatively easy, versatile and low cost way from a nuclear reactor or an accelerator.

- Silica shell offer smart characteristics in preventing agglomeration and perfectly well dispersed in liquid media.

- Applicable to use the GoldNanoTracer with small amount < 1 gram to strengthen the radiological safety features.

- Very small nano-scale approximately ~100nm that nearly free to gravitational influence and can play a role as efficient radioisotope carriers by modifying its surface accordingly.

- Provide excellent silica shell to protect gold core for high temperature under pressure applications to enhance its chemical stability.

-

ADVANCED NON-DESTRUCTIVE TESTING TECHNOLOGY

Leading Edge Non Destructive Testing Technology (LENDT) group is focusing on research and development of advanced Non Destructive Testing (NDT) technologies, building up innovative NDT solutions, and promoting and disseminating current NDT knowledge. Advanced NDT is a group of state-of-the-art NDT techniques that use certain type of energies to test and evaluate the integrity of critical industrial components. Our approach is done through rigorous quantitative and qualitative experiments and field test. Our main goals are to improve the reliability of testing results, produce up-to-date inspection approaches, and better inspection output in shorter time. The outcome will enhance the integrity and safety aspects of industrial components and reducing the probabilities of catastrophic damages. LENDT group has 4 laboratories as in Figure 1.

-

Acoustic Laboratory

Phased Array Ultrasonic (PAUT)

Phased Array Ultrasonic Testing (PAUT) is a technique that uses an array of ultrasonic piezoelectric transducers that is individually triggered, shown in Figure 2. This enables phasing, a way of controlling the generation of waves and provides the ability to bend, steer or focus the energy wave front. With PAUT, the detection probability of an inspection is increased and 10 times faster than conventional UT. PAUT can potentially be employed at almost any test where conventional UT has traditionally been used. The data presentation will be in A-Scan, B-Scan, C-Scan, and S-Scan. PAUT is a solution to the needs of inspection with high probability of detection while ensuring high inspection speed. It is the answer to the demands of the industry which requires rapid inspection without compromising reliability.

Figure 2: Phased array ultrasonic testing array probe

-

Electromagnetics Laboratory

Eddy Current Thermography (ECT)

Eddy current thermography combines the well-established inspection techniques; eddy current testing and thermography. This non-radiation approach is developed to evaluate qualitatively and quantitatively, electrically conductive material. It fulfills the requirement set by the industry in maintenance and inspection program. The technique is able to provide better and faster inspection results for a safer and economic industrial environment. The technique is applicable to detect and to some extent, characterize defects.

Figure 3: Experimental set-up of eddy current thermography system

Pulsed Eddy Current (PEC)

Pulsed eddy current (PEC) technique is based on inducing electrical currents in conductors and measuring the accompanying secondary magnetic decay signal generated through this process. During the inspection, the pulsating transient excitation induces eddy currents inside the sample. Discontinuities located near to the surface will affect the magnetic field distribution earlier than those located deeper inside the sample. Since PEC is rich with frequency components, information on identified defects at different depth can easily be acquired by exercising time domain signal analysis.

Figure 4: Pulsed eddy current system

-

Optics Laboratory

Laser Shearography

Laser shearography is a speckle technique developed to detect and reveal strain induced defects. The technique measures derivative phase change difference that quantitatively used to locate and analyze defects. The technique is less susceptible to environmental and mechanical noise compared to other speckle methods such as electronic speckle pattern interferometry (ESPI. The changes of optical phase due to displacement behavior are correlated to the nature and type of load imposed to the inspected object. A new system, Sniper Avantgarde, was developed to inspect critical industrial components and map stress distribution area.

Figure 5: Sniper Avantgarde for pipeline inspection

Figure 6: Results obtained from Sniper Avantgarde

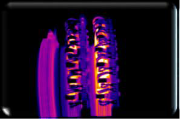

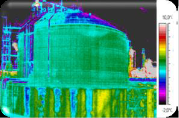

Infrared Thermography

Infrared thermography testing (IRT) is a technique of acquisition and analysis of thermal information from non-contact imaging devices. It is based on measuring the distribution of radiant thermal energy (heat) emitted from a target surface by the use of an infrared camera, and converting this to a map of radiation intensity differences (surface temperature map) or thermogram. The IRT is one of many select energy predictive maintenance services designed to save time and cost through early detection of any process that uses or produces energy. Advance notice of developing problems enables the necessary adjustments or repairs before costly, sometimes catastrophic failures occur.

The application of infrared thermography in electrical switch board

Thermal Inspections of motors, pumps, fans, bearings, compressors, heating elements, humidifiers etc. can be analyzed for faults and decrease in efficiency

Internal properties in walls and pipes such as building and cool room/oven insulation and furnace refractory breakdown and efficiency, scale build up, fluid build-up in composite structures etc. can be determined

-

Radiation Laboratory

Our main focus is producing better approach and procedure in radiographic testing of critical components through the application of digital image processing, advanced digital base technologies, and modelling and simulations. The laboratory main focus is to reduce an unnecessary exposure dose to the industrial radiation operators, enhancing inspection capabilities, and supporting the national needs in the application of Digital Industrial Radiography (DIR) instrumentations and technical knowledge.

Laser film digitizer

a-Si digital detector array

Film printer

Computed radiography (CR)

225 kVp X-ray generator

Analytical solution

-

MATERIAL TECHNOLOGY

The Materials Technology Group (MTEG) conducts basic and applied research in materials synthesis, characterizations, testing and protection, participates in national higher education learning by providing industrial and research training to students and support the national flagship research. Our objective is to acquire and share the knowledge and experience that are necessary for the development of new materials and technology and its applicability through innovative accomplishment. We aim to develop materials with properties that help to solve problems in different areas including radiation science, energy and environment by increasing their efficiency and performance, assuring their safety and sustainability besides reducing their cost and wastage.

The group also pursues its activity by engaging in long-term government prioritized research programmes in the framework of the Agency's main role, specific research projects funded by government and private bodies, development programmes and projects for the establishment and maintenance of the Agency's research infrastructure and provide services to the industry. The group has performed research on the topic of ceramic, metallurgy, corrosion protection, nano-materials, biomaterials, radiation shielding, radiation damage, electronic materials, minerals, sensors, preservation and consolidation of artefacts, nuclear instrumentation as well as modeling and simulation. In addition, the group is also well-equipped with a range of essential tools for the synthesis, characterization and testing of materials such as XRD, FESEM/EDX/WDX, SEM/EDX, EDXRF, WDXRF, Confocal Raman Spectrometer, AFM, STA, SAXS, SANS, Neutron Radiography, UV-Vis Spectrometer, Photoluminescence Spectrometer, Sparks Emission Spectrometer, Particle-Size Analyzer, Potentiostat, Corrosion Analyzer, Hardness Tester, Universal Testing Machines, Spin Coater, Sputter Coater and Electrospinning System.

Areas of research include:

-

Nanotechnology

- Synthesis and Characterization of Nanomaterials and Nanostructured Materials

- Radiation Driven Nanofabrication of Materials

- Development of Nano-electrocatalysts and Photocatalysts system for Renewable Energy Applications

- Development of Materials for Hydrogen Production, Storage and Utilization

- Development of Functional Materials for Sensors and Detectors

- Recycling of Waste to High-valued Nanomaterials or Nano-products

- Development of 3-D Scaffold Nanofibers

-

Metallurgy

- Development of Protective Coating Solution for Industrial Materials (Rust Converter)

- Development of Aluminum Based Alloys For Cathodic Protection

-

Nuclear Materials And Instrumentation

- Development of Radiation Shielding Materials

- Investigation of Radiation Damage in Materials

- Small Angle Neutron Scattering Facility

- Neutron Radiography/Tomography

-

Heritage Preservation

- Conservation, preservation and consolidation of artefacts

- Development of preservation and conservation techniques for artefacts

-

Development of Innovative Nuclear Reactor Technology – with the spin-off based on Thorium (FP0214D052 DSTIN), 2014 - 2018

This R&D program was under the national agenda for enhancing science, technology and innovation (DSTIN – Dasar Sains, Teknologi dan Inovasi Negara)Introduction

Thorium (Th), the future nuclear fuel, is found three times more abundant than uranium. It has all the energy efficiency and security characteristics – fertile, much less plutonium or other nuclear waste. Moreover, it is more proliferation resistance than uranium (U). Th (or Th+ uranium (U)) based reactors are slated to produce cheaper electricity and minimum nuclear waste, which makes this technology favoured as one of the alternatives for future energy generation options in Malaysia. We are also faced with public concerns and safety issues in the Rare Earth Extraction (REE) industry as thorium (Th) exists in Rare Earth Oxide (REO) waste residue, as well as in ex-tin mining tailings. Hence, by extracting and separating Th from the residue, we could resolve the public and safety concerns and creating safe, clean and economic REO extraction industries – in short tackling political, economic and strategic benefits in one go. Since the country has a significant number of REE industries and an established national nuclear research institute which is the Malaysian Nuclear Agency, there is a case for Malaysia to pursue further research in Th extraction to help industries producing radioactive free REO to create cleaner REE industries and free Th waste.

Lambakan amang yang merupakan sumber utama unsur torium dan nadir bumi

Majlis penyerahan kunci Loji Perintis Pemrosesan Mineral pada 6 Januari 2020

Thorium as national agenda

In 2013, Malaysia established a National Committee on Thorium to conduct the study and R&D activities to realise the use of Th as a strategic fuel for the future. The R&D program was developed and approved in 2014 for five years (2014 - 2018) and was completed in 2020. However, the strategy for the development of nuclear fuel from locally extracted Th was withdrawn before it was realised as the national policy was amended during the project implementation.

Among core technology projects and sub-projects implemented in 2014 – 2020 are as follows:

- Exploration and siting

- Thorium resource and supply

- Preliminary siting study on Small Modular Reactor (SMR) using U-Th fuel

- Pilot Plant engineering development to build the pilot plant for local mineral processing activities

- Development of radiation induced graft polymerisation for use as Th absorbent

- Immobilisation of radioactive waste from the extraction process

- Characterisation, extraction and purification of rare earth elements, Th and U from Malaysian rare earth ores

- Area monitoring system for thorium and rare earth laboratories and pilot plant

- Engineering software for radiation safety simulation

Project Objectives

- Identification of the distribution and to estimate the reserve of Th, U and REE in Malaysia

- Centralization of radiation monitoring station at various locations in Nuclear Malaysia

- Development of capacity building in Th, U and REE extraction

- Development of pilot plant for local mineral processing

Current R&D program

Currently, the R&D program is more focused on recovering and extracting rare earth oxide (REO) for non-nuclear fuel applications in line with the latest National policy towards the realisation of Wawasan Nuklear Malaysia 2030 and Wawasan Kemakmuran Bersama 2030.

Pemandangan luar loji dan keadaan di dalam Loji Perintis Pemrosesan Mineral

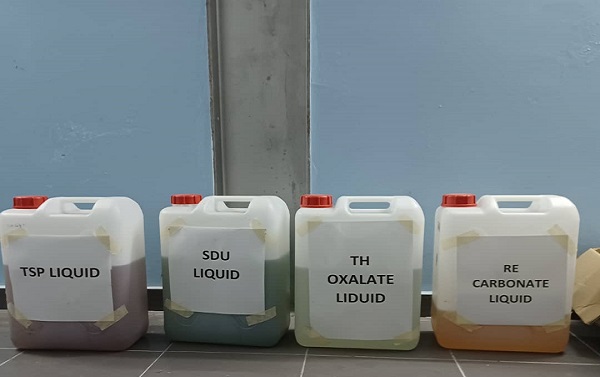

Produk awal Loji Perintis Pemrosesan Mineral

Produk akhir Loji Perintis Pemrosesan Mineral

Pengekstrakan unsur nadir bumi

Analisis unsur nadir bumi

- STRUCTURE INTEGRITY TECHNOLOGY

-

Ground penetrating radar (GPR)

Ground penetrating radar (GPR) use electromagnetic (EM) waves to detect and locate sub surface objects in most mediums such as soil or concrete. The EM waves are transmitted at high frequencies between 100 MHz up to 200 MHz from an antenna. The transmitted EM waves travel through the medium and reflect upon reaching a boundary of another medium with sufficient dielectric contrast. The reflected waves that travel back to the antenna are picked up and recorded. The time of flight and the intensity of the reflected waves contain information that can be interpreted to be depths and the nature of the reflectors. This enables GPR to be an excellent tool to detect size and locate subsurface objects. The material, size, shape and orientation of the reflector can also be estimated using GPR.

Malaysian Nuclear Agency has been pursuing R&D on the application of GPR as a solution to subsurface object detection since year 2003. Nuclear Malaysia has provided expertise to the public and private sector such as detection of war graves for the purpose of exhumanation and repatriation (Op Reunites and Op Te Auraki), detection of underground utilities, detection of archeological artifacts, detection of subsurface voids, concrete inspection, integrity determination of tunnel wall and etc. The vision of the agency is to become leaders in subsurface object detection and mapping.

-

Ground Electromagnetic Measurement (GEM)

GEM provides a rapid multifrequency technique for shallow geophysical exploration. Survey application includes ground contamination, hydrogeology, groundwater contamination mapping and archeological investigations. This highly portable hand-held instrument, when linked with active GPS tracking provides typical 1.5 ground point spacing and allows a surveyor to collect around 20,000 data points per hour over five frequencies. GEM uses an active EM signal to detect variations in subsurface conductivity.

-

TROXLER Density Gauge

A TROXLER Density Gauge is a tool used in civil construction and the petroleum industry as well as mining and archeology purposes. It consists of a radiation source that emits a cloud of particles and a sensor that count the received particles that are either reflected by the test material or pass through it. By calculating the percentage of particles that return to the sensor, the gauge can be calibrated to measure the density and inner structure of the material.

-

Ultrasonic Testing (UT)

Ultrasonic testing (UT) uses high frequency sound waves (typically in the range between 0.5 and 15 MHz) to conduct examinations and make measurement. UT can be used for flaw detection/evaluation, dimensional measurements, material characterization and more. It also can be used in the medical field (such as sonography, therapeutic, ultrasound ad etc.).

In general, UT is based on the capture and quantification of either the reflected waves (pulse-echo) of the transmitted waves (through-transmission). Each of two types is used in certain applications, but generally pulse echo systems are more useful since they are require one – sided access to the object being inspected.

-

Liquid Penetrant Testing – Surface Method

Liquid penetrant testing is one of the oldest and simplest NDT methods where its earliest version (using kerosene and oil mixture) dates back to the 19th century. This method is used to reveal surface discontinuities by bleed out of a colored or fluorescent dye from the flaw. The technique is based on the ability of a liquid to be drawn into a "clean" surface discontinuity by capillary action. After a period of time, called as 'dwell time', excess surface penetrant is removed and a developer applied. This act as a blotter that draws the penetrant from the discontinuity to reveal its presence.

-

Magnetic Particle Testing (MT)

Magnetic particle testing is one of the most widely utilized NDT method since it is fast and relatively easy to apply and part surface preparation is not as critical as it is for some other methods. This method uses magnetic field and small magnetics particles (i.e. iron fillings) to detect flaws in components. The only requirement from inspectability from standpoint is that the component being inspected must be made of ferromagnetic material (materials.

For further inquiries, please contact SISPA.